Impact drivers and drill tools often come in combination sets, and it’s easy to get confused by their functionalities and wonder which one is right for your task. Knowing the difference between a drill and an impact driver will improve your productivity, especially when working with different materials and fasteners. Let’s explore the essential differences between these tools and when you should choose one over the other.

What Is an Impact Drill?

An impact drill, often called a hammer drill, is a tool used primarily for drilling into tough materials like concrete, brick, and masonry. It combines regular drilling with a rapid forward hammering motion, which helps break through hard surfaces. When you turn on the impact feature, the drill bit not only spins but also “hammers” forward, making it ideal for heavy-duty tasks that require both rotation and force. People often use impact drills for projects involving concrete walls, stone foundations, and other dense materials where a standard drill might fall short.

Impact drills are popular in construction and renovation, as they can make quick work of challenging surfaces. However, they’re not typically used for driving screws, as the hammering action can damage the screw heads and is generally overpowered for delicate tasks.

What Is an Impact Driver?

An impact driver, in contrast, is specifically designed for driving screws and bolts into wood, metal, and other materials. Unlike an impact drill, an impact driver doesn’t use a forward hammering motion; instead, it applies a rotational impact that delivers bursts of torque, making it easier to drive screws without the tool getting stuck or slowing down. This powerful torque is perfect for longer screws and tougher fastening tasks, making impact drivers a go-to for carpentry, construction, and automotive work.

Impact drivers are generally more compact and lightweight than impact drills, which makes them easy to handle in tight spaces or overhead work. They don’t have a drill chuck but instead use a hexagonal chuck that accommodates driver bits, meaning they’re built for driving rather than drilling. For drilling holes, a regular drill or hammer drill is generally a better choice.

Difference Between Impact Driver And Drill

How They Work

A drill operates simply. The chuck of a drill spins in a single direction when you’re driving screws or drilling holes. The speed is controlled by two things: the pressure on the trigger (usually variable) and your gear setting. Most drills have two or sometimes three-gear settings, affecting both speed and torque.

An impact driver, on the other hand, uses a different driving mechanism altogether. While it also has a variable-speed trigger, it applies additional force, a rotational impact, when it encounters resistance, making it ideal for driving fasteners into tougher materials.

Bits and Chucks

One of the key differences is in the chuck. Drills have three-jaw chucks, which let you switch between a variety of bit sizes — from tiny 1/16-inch bits to much larger options. On the other hand, impact drivers use only one type of bit: a 1/4-inch hex bit. These bits often feature indentations and a torsion zone to handle the added force.

Clutch vs. No Clutch

Here’s where the drill shines for delicate tasks. Drills come with a clutch — a feature that allows control over the torque applied. Setting the clutch to a low number prevents stripping screws on delicate materials like hinges. In short, a drill knows when to stop.

Impact drivers, however, lack a clutch and will continue driving screws until they strip or break, which is fine for tough materials but not for delicate tasks.

Noise

Impact drivers are effective, but they’re also noisy. If you’ve never used an impact driver before, be prepared for the obnoxious noise. Some models now feature quieter designs, but they’re still generally louder than drills.

Also, using an impact driver for general drilling tasks can wear down the tool and bits faster. While you can technically drill holes with an impact driver if you’ve got the right bits, it’s not ideal. Regular drills are built for controlled, continuous motion, making them far better at drilling holes consistently and precisely.

When To Use an Impact Drill

Controlled Power for Drilling

If you’re drilling holes, especially into softer materials, the drill is your go-to. The clutch feature allows you to set the resistance level, making it ideal for everyday tasks. The drill’s compatibility with a wide range of bits—from masonry to wood—offers a level of versatility that an impact driver simply can’t match.

The gear system is another reason to pick up a drill. When drilling into tougher materials like metal, dropping the drill into a lower gear gives you the torque you need without sacrificing control. The variable speed adjustments that most drills offer ensure you get the best performance for the task at hand.

Delicate Work

Working with delicate materials like cabinetry or installing door hinges? The drill’s clutch will prevent accidental over-driving, making it the right tool to get the job done cleanly. The last thing you want is to strip multiple screws because your tool applied too much torque.

Hammer Mode for Tough Surfaces

Many drills also offer a hammer mode. When you need to drill into concrete, rock, or other hard surfaces, hammer mode makes a difference. It works by mimicking a hammer’s action while spinning, adding downward force. If you’re thinking of using an impact driver for this kind of job, think again—it’s simply not designed for masonry.

When To Use an Impact Driver

It’s All About Torque

Impact drivers are designed to deliver serious power where it’s needed most — driving fasteners. If you’re working with lag bolts, long deck screws, or screws into hardwood, the rotational impact ensures the fastener goes in smoothly without stripping or stalling. For tasks that demand both speed and sustained power, such as framing, heavy machinery assembly, or automotive repairs, an impact driver is your best friend.

No More Kickback

Kickback happens when the bit in a regular drill catches or “binds” in what you’re drilling, causing the whole tool to spin instead of the bit. This can be rough on your wrists or shoulders. Impact drivers avoid this thanks to that rotational impact mechanism, which keeps the tool steady even if the bit hits a snag.

Compact for Tight Spaces

Compared to drills, impact drivers tend to be more compact. If you’re working in tight quarters — under sinks, in attics, or any spot where space is limited — you’ll appreciate the smaller, shorter body of an impact driver. Some brands make them even tinier, which can be a game-changer for certain jobs.

Best Impact Drill

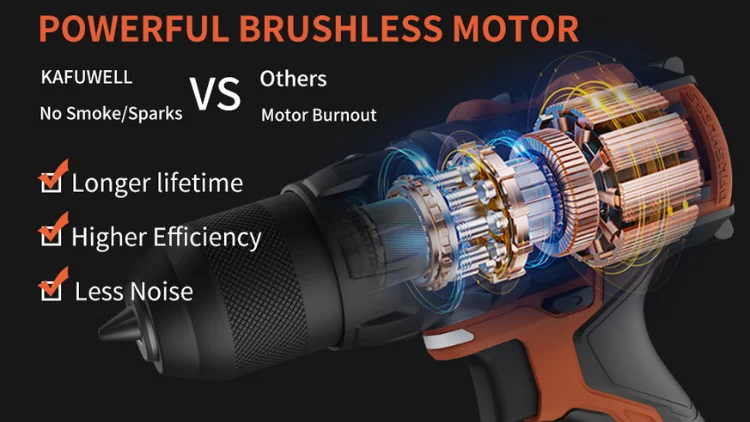

At KAFUWELL, we offer a wholesale selection of brushless power tools designed for professionals who demand high performance and reliability. Whether you need a drill, saw, or impact wrench, our carefully selected range of tools will meet the needs of your business and help you get the job done more efficiently.

If your project requires an impact drill, then I recommend this brushless cordless impact drill with a dual-speed function and a 20V power system. It has a maximum torque of 150N.m, which ensures precise and efficient drilling in wood, steel, and other materials. It also has essential features for professional and home use such as reverse rotation, variable speed, and LED lighting.

Can an Impact Driver Drill Holes?

Yes, an impact driver can drill holes, but only if you’ve got the right bits, specifically those rated for impact. These are designed to handle the additional torque. So, while you can drill holes in some scenarios, like running electrical wire through studs, other drilling tasks, such as metalwork or precision drilling, are better left to a standard drill.

You can even get adapters like a three-jaw chuck for an impact driver, which allows you to use regular drill bits. But bear in mind that the performance won’t match that of a dedicated drill.

The Final Verdict

So, how do you decide which one’s right for the job? It’s actually pretty simple most of the time:

- Need to drill a hole? Use a drill.

- Need to drive a fastener? Use an impact driver.

Of course, there are exceptions. If you’re drilling a small, easy hole and the impact driver’s already out, it might be more convenient to keep using it. But for precision work, drilling larger holes, or handling delicate screws, a drill is the safer bet.

Ideally, you’ll have both tools on hand. A drill and impact driver can be an unbeatable duo. Drill your holes with a regular drill, and drive fasteners with your impact driver. It’s about using the right tool for the specific task.

Here’s a tip: try pairing a compact drill with a compact impact driver for a balanced, space-saving set that’ll cover almost all your DIY needs.