If you enjoy working with tools and you are also interested in running a real business, becoming a power tool distributor might be a very good fit for you. This kind of business can provide relatively stable income, because construction, repair, and maintenance never really stop.

In this guide, you will learn how the distribution model works, how to choose your market, how to find and work with manufacturers, and what it takes to build a sustainable and scalable distribution business.

Understanding Power Tool Distribution

What Does a Power Tool Distributor Actually Do?

A power tool distributor acts as the bridge between manufacturers and buyers. You do not need to produce tools yourself. Instead, you:

- Purchase products from one or more manufacturers

- Hold inventory or coordinate shipments

- Sell and support these products for retailers, contractors, online sellers, and industrial users

You are responsible for product selection, inventory planning, pricing, and sales. Manufacturers focus on engineering and production.

This is different from:

- Retailers, who mainly sell to end users and usually purchase from distributors or national importers

- Pure importers, who bring products into a country but may not actively manage ongoing sales and customer relationships

As a distributor, you sit in the middle of a long-term value chain and can build a base of repeat customers who rely on you as their main supplier.

Why the Power Tool Industry Is So Attractive

The power tool industry has several characteristics that make it very attractive for distributors:

- Demand is driven by construction, home renovation, maintenance, and industrial projects

- Corded tools are steadily shifting toward cordless platforms

- New technologies such as brushless motors and advanced batteries create regular upgrade cycles

- DIY culture and content creators encourage more people to buy tools

These trends create continuous demand rather than a one-time spike. Distributors who can provide stable quality and strong support are able to build a loyal customer base over many years.

Step 1: Identify Your Target Market

Choose the Customer Groups You Want to Serve

You do not need to serve every potential customer from day one. A more effective approach is to focus on one or two clearly defined segments and design your business around them. Typical segments include:

- Hardware stores and local shops: they need a stable product line, transparent pricing, and reliable delivery

- Construction and trade companies: they value durability, uptime, and technical support

- E-commerce resellers: they need competitive pricing, high quality photos and descriptions, and products that are ready to list online

- Industrial buyers and workshops: they may require specialized tools, larger quantities, and formal procurement processes

Each group has different expectations for price, product range, and service. Defining your target customers will help you decide what to sell and which suppliers to work with.

Analyze Local Demand

Before you start, research your local market:

- Which power tool brands are already strong and well established

- Which categories sell the fastest, such as cordless drills, impact wrenches, grinders, or saws

- Local voltage standards and plug types

- Typical price levels for DIY tools versus professional tools

You can gather information from hardware stores, trade shows, online marketplaces, and conversations with contractors and tradespeople. This will help you avoid bringing in products that are overpriced or not suited to how users in your market actually work.

Step 2: Choose the Right Product Categories

High-Demand Entry-Level Tools

For beginners, it is usually best to start with a focused and proven product range, for example:

- Impact drills and drill drivers

- Impact wrenches

- Angle grinders

- Circular saws and reciprocating saws

- Cordless combo kits and starter kits

- Batteries and chargers that match the main tools

These products are widely used across many scenarios, from home users to professionals. They help you drive sales volume and build brand awareness.

Professional Grade vs DIY Grade

You also need to decide whether you want to focus on:

- DIY or home-use tools: lower price, simpler features, medium durability

- Professional grade tools: higher price, stronger performance, better components, and usually longer warranty terms

You can sell both levels at the same time, but it is important to know which one is your core business. Professional users care more about torque, runtime, and durability. DIY users pay more attention to price and ease of use.

Private Label vs Existing Brands

There are two main strategies:

- Distributing existing brands: easier to get started. If a brand is already known, trust builds faster, although margins may be lower and competition may be stronger

- Developing a private label: you work with a manufacturer to put your own brand on the tools. This gives you better control over pricing and long-term value, but you need to invest more in marketing and customer support

Many distributors begin by wholesaling existing brands from manufacturers, then launch their own private label line once they better understand market expectations.

Step 3: Find a Reliable Power Tool Manufacturer

Qualities a Manufacturer Should Have

Your choice of manufacturer will directly affect your reputation in the market. When evaluating factories, consider the following:

- Real experience producing power tools, not just general hardware

- Factory size and production capacity

- Engineering and R&D capability for new models

- Certifications such as ISO systems and safety approvals for your target markets

- Existing customers and export history

Manufacturers that already produce for well-known brands usually have higher standards and more stable production processes.

Evaluate Product Quality

Request samples and test them under real working conditions:

- Measure changes in torque, speed, and runtime across repeated cycles

- Check ergonomics, grip, vibration, and noise levels

- Inspect the housing, assembly quality, and the fit of moving parts

- Try different loads and materials, such as wood, concrete, and metal

- Evaluate battery performance and charging time

- Check safety features, including overload protection and electronic brake

- Monitor temperature rise during heavy use

Understanding Standards and Safety Requirements

You should be familiar with different types of standards, for example:

- ISO 9001: the world’s most widely recognized and respected quality management system standard

- ISO 14001: environmental management system certification that helps companies minimize their environmental impact

- OHSAS 18001 / ISO 45001: health and safety management certifications designed to help companies improve workplace safety and reduce the risk of accidents and injuries

- CE marking: indicates that products meet European Union health and safety requirements

- UL certification: indicates that products have been tested and certified to meet certain safety and performance standards

Understand MOQ, Lead Times, and Pricing

Manufacturers usually set minimum order quantities for specific models or configurations. Make sure you clarify:

- The MOQ for each tool and each kit. For example, Kafuwell offers very low MOQs. You can start with a single carton and mix different products in that carton, which makes it much easier to test the market

- Standard lead times for first orders and repeat orders

- How they handle urgent replenishment or peak season demand

Pricing is affected by volume, level of customization, packaging, and exchange rates. You should focus on landed cost rather than just ex-factory price, and strike a balance between cost, quality, and the strength of the after-sales support system.

Beyond price and basic product quality, you should also understand how a power tool manufacturer supports its distributors.

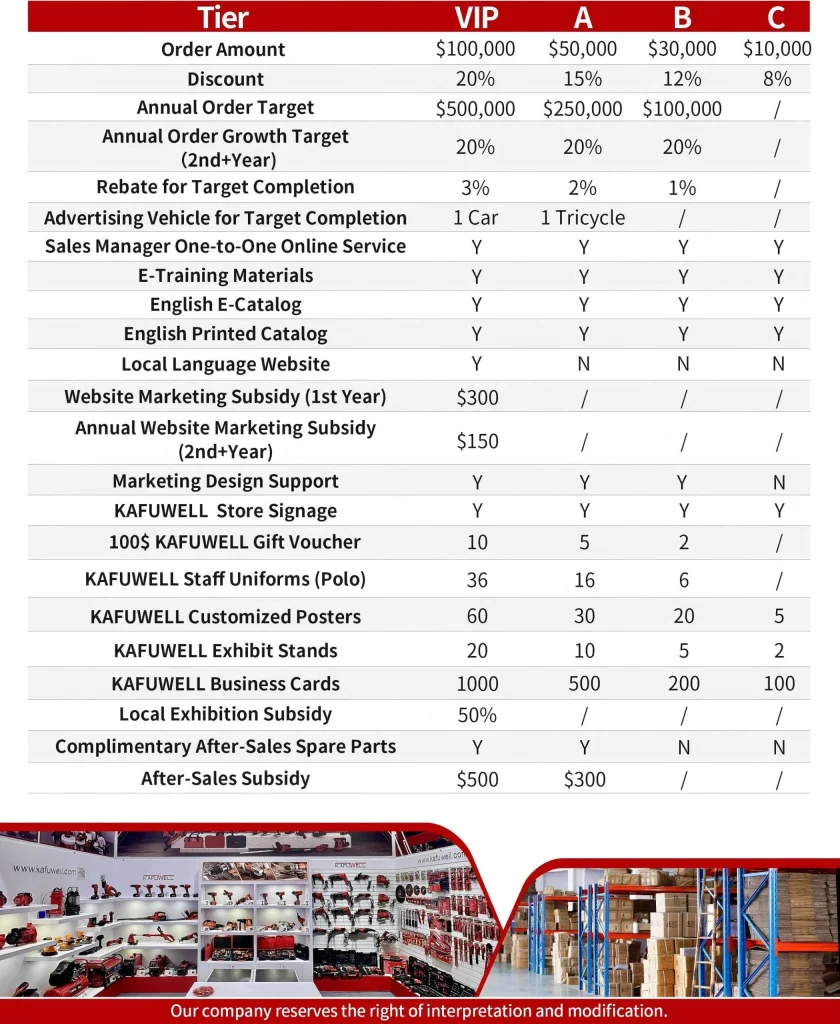

For example, Kafuwell’s distributor policy uses clear tiers based on annual order volume and offers different discounts, marketing support, and after-sales benefits, as shown below.

How to Approach Power Tool Manufacturers and Wholesale Suppliers

You can find suppliers through several channels, including:

- Relevant trade shows, such as the China Import and Export Fair (Canton Fair) and Asia Pacific Sourcing

- Online directories and B2B platforms, such as Alibaba, Global Sources, and LinkedIn

- Using search engines like Google and searching terms such as “wholesale power tools” or “power tool manufacturers” to find official manufacturer websites, then going to their partnership pages, such as “Partner with KAFUWELL”, to learn about distribution or dealership options

- Asking contractors and store owners which brands they trust

- Obtaining vetted manufacturer lists through hardware industry associations or tool industry organizations

When you reach out proactively, be ready to introduce:

- Your company background and the region or market you serve

- Your cooperation intent, for example distribution, dealership, wholesale, or OEM/ODM

- The expected size and budget of your first order, so that the manufacturer can quickly assess and respond

You should also request catalogs and price lists and ask about partnership policies so the manufacturer can evaluate your needs and reply more efficiently.

learn more:Top 9 Power Tool Manufacturers in China

Step 4: Build Your Supply Chain and Logistics

Choose Your Supply Method

There are several ways to move goods from the factory to your customers:

- Direct import and local warehousing: you bring containers into your country or region, store them, and then supply your network

- Third-party logistics (3PL): you work with a logistics provider who handles warehousing and shipping on your behalf

- Hybrid models: you keep fast-moving items in stock while using more flexible arrangements for slower movers

The right model depends on your sales volume, market size, and cash flow.

Shipping and Customs Considerations

For international supply chains, shipping and customs are critical:

- Use sea freight when you want to optimize cost, and air freight when speed is more important

- Ensure that packaging and labels comply with regulations in the destination market

- Understand import duties, VAT, and any safety requirements for power tools and batteries

Inventory Planning

Good inventory planning helps you avoid two major risks: stockouts and excess inventory. To manage your stock effectively, you can:

- Analyze the sales speed of each SKU

- Set reorder points based on average lead times and safety stock

- Create seasonal plans for peak periods such as spring construction season

Even a simple spreadsheet-based system can work at the beginning, as long as you track your data carefully.

Step 5: Develop Your Pricing and Profit Strategy

Understand Profit Structures in the Tool Industry

Profit margins vary by product type and channel. In general:

- Accessories often have higher margins than core tools

- Professional tools can deliver higher profits than entry-level DIY tools

- Distributors may offer different price levels based on volume or customer type

List your cost structure clearly, including product cost, freight, customs, warehousing, and overhead.

Avoid Competing Only on Price

Instead of fighting purely on price, you can add value by:

- Keeping inventory stable and reliable

- Providing knowledgeable pre-sales and after-sales support

- Establishing clear warranty and repair processes

- Offering training or demonstration sessions for your customers

These strengths help you stand out from competitors who only cut prices.

Step 6: Build Your Sales Channels

Your sales channels determine where and how you find customers. Common routes include:

- Local retail partners and hardware stores: you sell to them at wholesale prices and they serve end customers

- Direct sales to contractors and factories: visiting sites, offices, and plants, where relationships and service are critical

- A warehouse front desk or showroom: local workers can pick up orders in person, which is also suitable for demonstrations and on-site sales

- Online stores or e-commerce platforms: you can reach more regions and compete on price, delivery speed, and product information

Many small distributors use a mix of channels. For example:

- Mainly supplying local contractors and stores

- Using their own trucks to offer local delivery

- Operating an online catalog or simple web shop so customers can place replenishment orders 24 hours a day

When you are just starting, focus on one or two primary channels first. Once operations are stable, you can gradually expand.

Conclusion

If you are at the starting stage and looking for a stable supplier, you are welcome to contact the Kafuwell team to get a distribution plan and suggestions tailored to your market.

Kafuwell has many years of practical experience and a clear, tiered distributor policy. Based on annual order volume, it offers different price discounts, marketing support, and after-sales programs. This helps you build a healthier profit structure and more reliable service capability, so you can keep expanding your local market with confidence.