If you’ve ever used a power tool, you’re probably aware that regular maintenance is crucial to keep it running smoothly. One of the most important components of many power tools is the carbon brush. But how long does a carbon brush last in power tools? This is a common question for both DIY enthusiasts and professionals who rely on these tools for their work. Understanding the lifespan of carbon brushes and how to care for them is essential for maximizing the performance of your equipment and ensuring that your tools last as long as possible.

In this article, we will explore the factors that influence the lifespan of carbon brushes, how to tell when they need to be replaced, and tips to extend their life. Whether you’re an amateur using a drill for home projects or a contractor with multiple power tools, knowing more about your tools’ carbon brushes will help you keep them in top condition.

What Are Carbon Brushes?

Before diving into how long carbon brushes last, it’s important to first understand what they are and how they function. Carbon brushes are small, rectangular blocks made from a mix of carbon and other materials. These brushes are a crucial part of the motor in many power tools, such as drills, saws, grinders, and other electric motors.

Their primary role is to transfer electricity between the rotating part of the motor (the armature) and the stationary part (the commutator). As the motor runs, the carbon brushes wear down gradually due to the friction between the brushes and the commutator. The process of this wear and tear is inevitable, but the rate at which it happens depends on several factors, which we’ll discuss in detail later.

Carbon brushes are essential for ensuring the smooth operation of the motor, but as they wear out, the performance of the power tool begins to decrease. This is why it’s so important to monitor their condition and replace them when necessary.

Average Lifespan of Carbon Brushes

So, how long do carbon brushes typically last in power tools? The lifespan of carbon brushes can vary widely depending on the type of tool, how frequently it’s used, and the working conditions. On average, carbon brushes in power tools tend to last anywhere between 50 to 100 hours of use, but this number can go up to 200 hours or more in certain professional-grade tools.

For home use, carbon brushes may last longer due to less frequent usage. For example, a homeowner using a drill a few times a month could expect the carbon brushes to last several years. However, for professionals who use their tools daily in heavy-duty tasks, the lifespan can be significantly shorter.

It’s also important to note that tool power plays a role in the lifespan of carbon brushes. High-powered tools, such as industrial-grade drills or angle grinders, tend to wear out carbon brushes faster than smaller, less powerful tools. This is because they exert more strain on the brushes as they work harder to handle tougher materials and longer work hours.

Factors That Affect the Lifespan of Carbon Brushes

The lifespan of carbon brushes in power tools is influenced by several factors. Understanding these factors will help you manage and maintain your tools more effectively, ensuring that the brushes last as long as possible and your tools perform optimally.

1. Usage Frequency

The most significant factor that affects the lifespan of carbon brushes is how often the power tool is used. Power tools that are used regularly and for long durations will experience faster wear and tear on the carbon brushes. For instance, a tool that is used for several hours a day, every day, will naturally wear out the carbon brushes much faster than one that is used occasionally for home repairs.

If you’re using a tool for heavy-duty tasks like drilling through concrete or cutting metal, expect the brushes to wear out more quickly due to the added stress. Conversely, light-duty tasks, such as drilling into wood or light materials, will cause less strain on the brushes.

2. Working Environment

The environment in which you use your power tools can have a major impact on the carbon brush’s lifespan. Tools used in dusty or dirty environments—such as construction sites—are likely to experience faster carbon brush wear. The dust and debris can cause friction, which accelerates the rate at which the brushes wear down.

Similarly, tools used in highly humid or wet environments can also experience more rapid brush wear due to the moisture causing corrosion or increased friction between the brush and commutator.

3. Power Tool Type and Power

The type of power tool you own will influence how long the carbon brushes last. High-powered tools that perform heavy-duty work, like angle grinders or demolition hammers, will typically cause carbon brushes to wear faster than lighter tools like cordless drills or screwdrivers.

Tools with high torque or more complex motor systems will naturally strain the carbon brushes more than those with simpler or lower-power motors. As mentioned earlier, industrial-grade tools designed for professional use generally have shorter carbon brush lifespans compared to household tools.

4. Proper Maintenance

Regular maintenance of your power tools can greatly extend the lifespan of carbon brushes. For example, keeping your tool clean by wiping away dust and debris after each use can prevent dirt from getting into the motor and causing extra wear on the carbon brushes. Additionally, ensuring that the brushes are seated properly and the commutator remains smooth can reduce friction and prolong the life of the brushes.

Checking the carbon brush spring tension and making sure the brush holder is clean can also help reduce wear. Most tools will have a maintenance guide, so be sure to follow the manufacturer’s recommendations for optimal care.

5. Quality of the Carbon Brushes

Not all carbon brushes are created equal. The quality of the carbon brush plays a significant role in how long it will last. Low-quality or poorly manufactured brushes may wear down much quicker than higher-quality brushes. When purchasing replacements, it’s important to choose brushes that are designed specifically for your tool’s model, as this ensures better compatibility and durability.

How to Tell When Carbon Brushes Need to Be Replaced

It’s crucial to be proactive about replacing carbon brushes before they cause significant damage to your tool. Fortunately, there are several signs you can look out for to determine when it’s time for a replacement.

1. Loss of Power

One of the first noticeable symptoms of worn-out carbon brushes is a loss of power in the tool. If you notice that your power tool isn’t performing as efficiently as it once did, this could be a sign that the carbon brushes are too worn down to properly conduct electricity.

2. Excessive Spark or Noise

If you begin to see excessive sparking around the motor or hear unusual noises coming from the tool, it’s time to check the carbon brushes. Excessive sparking indicates that the carbon brushes are no longer making good contact with the commutator, which can lead to further damage.

3. Overheating

Another sign that the carbon brushes may need replacing is if the tool begins to overheat during normal operation. If the tool is running hot and showing signs of distress, it may be because the brushes are not properly aligned or are creating too much friction.

4. Visual Inspection

The most reliable way to know if your carbon brushes need replacing is through a visual inspection. If the carbon brush has worn down to about a quarter of its original size, it’s time to replace it. If you’re unsure about how to inspect the brushes, consult your tool’s user manual for instructions on how to access and inspect the brushes.

Tips to Extend Carbon Brush Lifespan

Extending the lifespan of carbon brushes not only helps reduce maintenance costs but also ensures that your power tools perform at their best for longer. Here are some practical tips to help you get the most out of your carbon brushes:

1. Regular Cleaning

Regular cleaning is one of the most important steps in maintaining your power tools and extending the life of the carbon brushes. Dust, dirt, and debris can get lodged in the motor, causing friction and accelerated wear. After each use, take a few moments to wipe down your tools, especially around the carbon brush area. Use a soft cloth to remove visible dirt and dust, and for deeper cleaning, use compressed air to blow out any particles from the motor casing.

2. Avoid Overloading

One of the most common causes of premature carbon brush wear is overloading the tool. When using power tools, it’s essential to avoid forcing them beyond their designed capacity. For example, pushing a drill too hard when drilling through hard materials can cause the motor to work harder than necessary, leading to faster brush wear. Always follow the manufacturer’s instructions for maximum load to avoid unnecessary stress on the tool and its components.

3. Proper Storage

Storing your tools properly when they’re not in use can help prevent damage to the carbon brushes. Avoid leaving tools in damp or extremely hot environments, as these conditions can lead to corrosion and the premature wearing down of brushes. Instead, store your tools in a cool, dry place, and use tool boxes or protective covers to shield them from dirt and moisture.

4. Lubricate Regularly

Some power tools require regular lubrication to ensure the moving parts function smoothly. Check your tool’s user manual to determine whether it requires lubrication and follow the recommended guidelines. Proper lubrication reduces friction, which can help minimize wear on both the carbon brushes and other components of the motor.

5. Use the Right Brushes

Choosing the right carbon brushes for your power tool is critical for maintaining tool performance and extending brush life. Always ensure that the replacement brushes you purchase are the right size and type for your specific tool. Using incorrect brushes can lead to improper contact with the commutator, which can cause excessive wear and motor damage.

How to Replace Carbon Brushes

Replacing carbon brushes is a relatively simple process, but it’s important to follow the right steps to ensure that the new brushes are installed properly and that your tool continues to function at its best. Here’s how to do it:

1. Disconnect the Tool

Before starting the replacement process, make sure the power tool is turned off and unplugged from any power source. If it’s a cordless tool, remove the battery to ensure safety during the process.

2. Remove the Motor Housing

Most tools will have a motor housing or cover that needs to be removed in order to access the carbon brushes. Depending on the model, this may require unscrewing a few screws. Be sure to keep the screws safe for reassembly later.

3. Inspect the Brushes

Once you’ve removed the motor housing, you should be able to see the carbon brushes. Inspect them carefully for wear. If the brushes are worn down to about one-quarter of their original size, it’s time for a replacement.

4. Remove and Replace the Brushes

To remove the worn brushes, gently slide them out of their holders. Depending on the tool, the brushes may be held in place with springs or clips. When inserting the new brushes, ensure they are seated properly and make good contact with the commutator.

5. Reassemble the Tool

Once the new brushes are in place, reassemble the motor housing and tighten any screws that were removed. Make sure everything is securely fastened before powering the tool back on.

Read more: How to Replace the Carbon Brushes in a Drill?

Impact of Carbon Brush Life on Power Tool Performance

The performance of your power tool is directly related to the condition of the carbon brushes. Worn-out brushes not only reduce the efficiency of the motor but can also cause damage to the commutator, which could lead to costly repairs. Here’s why maintaining carbon brushes is crucial:

1. Efficiency Loss

As carbon brushes wear down, they make less contact with the commutator. This reduces the tool’s ability to operate efficiently and may cause a noticeable drop in performance. The tool might run slower or lose power during use, making it less effective for tasks.

2. Risk of Motor Damage

If the carbon brushes are left unchecked and continue to wear down, they can cause arcing and sparking at the commutator, which may lead to motor damage. In severe cases, this can result in the complete failure of the motor, requiring expensive repairs or a full replacement of the tool.

3. Increased Operating Costs

Neglecting to replace worn carbon brushes can result in higher operating costs. Tools with worn-out brushes consume more energy, perform less effectively, and have a higher risk of breakdown. By replacing the brushes on time and performing regular maintenance, you can reduce the need for costly repairs and extend the lifespan of your tools.

Conclusion

Understanding the lifespan of carbon brushes and knowing when to replace them is key to keeping your tools performing at their best and extending their lifespan. Reduce downtime and avoid costly repairs.

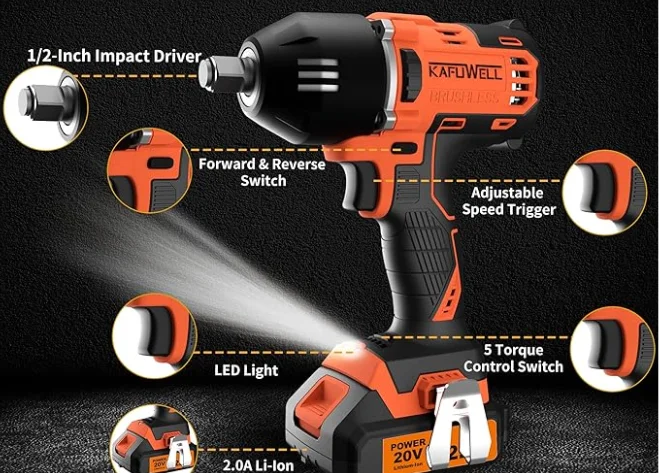

Ready to upgrade your power tools? Whether you’re looking for durable brushed power tools or efficient brushless power tools that eliminate the need for carbon brush replacements, we have you covered. Explore our power tool range today and experience the superior power and long-lasting performance they bring to your projects!