Impact sockets and chrome sockets differ in far more than just color. Their materials, construction, wall thickness, finish, and retention features are designed for very different purposes. This guide will break down those differences and show you exactly when to choose each.

What Are Impact Sockets?

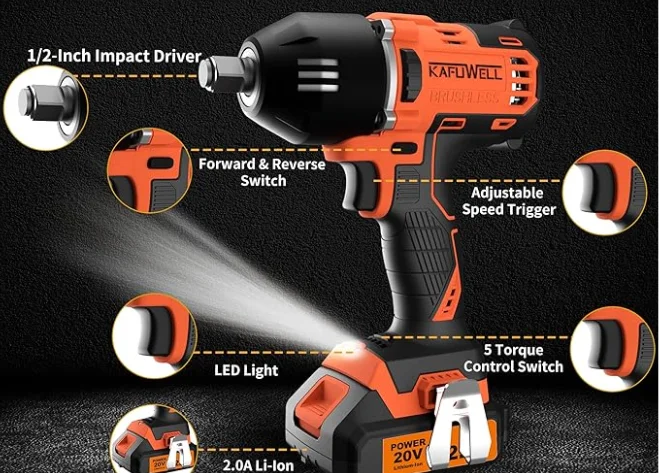

Impact sockets are built specifically for power tools that deliver hammering torque—such as pneumatic or cordless impact wrenches/drivers. Their job is straightforward: withstand repeated shock loads without cracking and stay securely locked on the tool’s anvil even during heavy blows.

Materials & Heat Treatment

Typically made from chromium-molybdenum (Cr-Mo) or other high-toughness steels, impact sockets are heat-treated to maximize toughness over hardness. This makes them less brittle and more resistant to fracture under impact, though they may feel slightly less “crisp” than chrome sockets when used by hand.

Design Features

- Thicker walls and reinforced geometry to absorb and distribute impact forces.

- Matte black phosphate or black oxide finish that resists flaking under repeated blows and makes size markings easier to read.

- Retention features at the drive end—such as through-holes and grooves—for use with a detent pin and O-ring or a pin-detent anvil. These help prevent the socket from flying off during hammering or overhead work.

Best Applications

Wheel lugs, suspension hardware, large or rusted fasteners, and any job where torque spikes sharply in pulses. If the tool hammers, it needs an impact-rated socket.

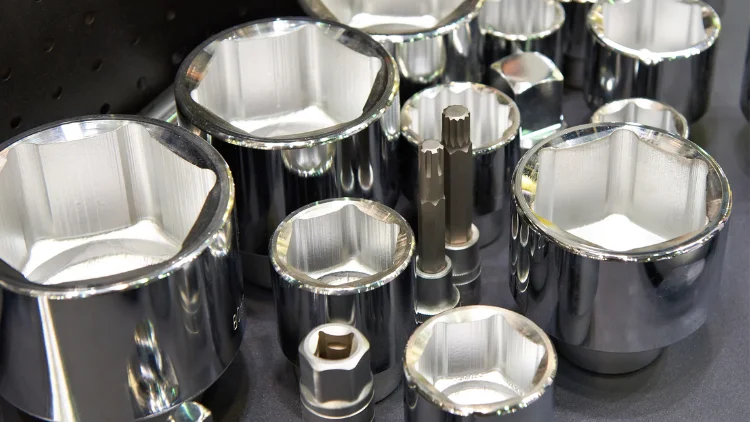

What Are Chrome (Standard) Sockets?

Chrome sockets—often called “standard” sockets—are made for hand tools like ratchets, breaker bars, and torque wrenches. They are designed for smooth, controlled torque application with precise, repeatable engagement on the fastener.

Materials & Heat Treatment

Usually made from chromium-vanadium (Cr-V) or similar steels, chrome sockets are heat-treated for hardness and wear resistance. This gives them a crisp fit and sharp edges that make them ideal for precise work with hand tools.

Design Features

- Thinner wall profile for better access in tight spaces, such as under the hood or behind brackets.

- Polished chrome plating that resists corrosion and wipes clean easily.

- Standard detent groove for ball-bearing retention; no through-holes since hand tools don’t require the same level of socket retention as impact tools.

Best Applications

Precision assembly, maintenance, and torque-critical work where access and control matter more than sheer impact durability. They’re also ideal for industries where cleanliness and corrosion resistance are important—like HVAC, food service equipment, or medical device maintenance.

Impact vs. Chrome — Key Differences at a Glance

| Feature | Impact Sockets | Chrome (Standard) Sockets |

| Tool Compatibility | Impact wrenches/drivers (air & cordless) | Ratchets, breaker bars, torque wrenches |

| Primary Goal | Withstand shock without cracking | Deliver precise fit with hand torque |

| Material & Heat Treat | Cr-Mo; tuned for toughness | Cr-V; tuned for hardness |

| Wall Thickness | Thicker for impact resistance | Thinner for tight access |

| Finish | Matte black (phosphate/oxide) | Polished chrome |

| Retention | Through-hole + groove for pin/O-ring or pin-detent anvils | Standard detent groove only |

| Typical Use | Lug nuts, suspension, rusted or large fasteners | General maintenance, torque-controlled work |

| Safety Note | Must be used with impact tools | Never use on impact tools |

One set cannot replace the other. Use impact sockets for impact tools; use chrome sockets for precise, controlled torque and tight spaces.

When to Use Impact Sockets

- Any tool that hammers. Impact tools deliver torque in blows—impact sockets are designed to handle that abuse and greatly reduce the risk of cracking or shattering.

- Automotive service. Wheels, hubs, suspension components, and subframe bolts benefit from the combination of impact tools and impact-rated sockets.

- Heavy shop or industrial use. Structural bolts, machinery teardown, and high-duty-cycle assembly lines rely on the durability and secure retention of impact sockets.

- Overhead or delicate-area work. Use a pin and O-ring or a pin-detent anvil to keep sockets locked in place and avoid drops.

- Reduce rework and injuries. The right choice helps prevent chrome flaking, chipped corners, and flying debris—protecting both fasteners and technicians.

When to Use Chrome (Standard) Sockets

Chrome sockets are the right choice for hand-applied torque where control and repeatability matter.

Ideal Scenarios

- Torque-critical assembly/service. Engine components, brake calipers, valve covers, and transmission pans—anything with a specified torque value—are best handled with chrome sockets and a calibrated torque wrench.

- Tight spaces. The thinner walls make it easier to reach fasteners in cramped locations where impact sockets may be too bulky.

- General maintenance. Interior trim, small hardware, appliances, and equipment panels often benefit from the lighter weight and better access of chrome sockets.

- Finish-sensitive environments. Chrome plating resists corrosion and cleans easily, making it a good fit for HVAC, food processing, or medical settings.

Tips

- Use 6-point sockets for high-torque or worn fasteners; use 12-point for faster alignment where torque is moderate.

- If a fastener won’t move with a chrome socket, switch to an impact setup—don’t force it.

Safety Guidelines for Both Types

- Match the socket to the tool. Impact sockets for impact tools; chrome sockets for hand tools.

- Never use chrome on an impact tool. The hard plating and hand-tool heat treat make them prone to cracking under repeated blows.

- Check retention on impact tools. Use pin and O-ring or pin-detent on large drives and overhead work.

- Wear eye protection. Even with correct use, fastener failure can eject debris.

- Inspect before use. Discard sockets with cracks, spread drive ends, heavy rounding, or peeling plating. Replace any that have been dropped from height or overloaded.

- Stay within tool limits. Follow the tool manufacturer’s recommended air pressure or torque settings.

- Use extensions/adapters carefully. For impact tools, only use impact-rated accessories.

- Store clean and organized. Keep impact and chrome sockets separate to prevent mix-ups.

Industry Standards to Look For

- ASME B107.110 — Specifies performance and safety requirements for sockets, handles, and attachments, including proof torque testing for impact tools.

- ISO 1711-1 — Sets minimum hardness and torsional strength for hand-operated sockets, making it the benchmark for chrome sockets.

Buying Guide

- Coverage (SAE & Metric, Drive Sizes) — Start with 3/8″ chrome (both SAE and metric) for general use, add 1/2″ deep impact sockets for wheels and suspension, and 1/4″ chrome for small assemblies.

- 6-Point vs 12-Point — 6-point for high torque, 12-point for quicker engagement.

- Deep vs Standard — Deep sockets for long studs or recessed nuts; standard for tighter spaces.

- Markings & Legibility — Large, high-contrast markings (stamped + laser-etched) are easier to read.

- Retention Compatibility — Match sockets to your tool’s anvil type: pin-detent for maximum hold, friction ring for quick changes.

- Material & Finish — Cr-Mo matte black for impact; Cr-V polished chrome for hand tools.

- Warranty & Compliance — Lifetime replacement is common, but quick claim service is key.

FAQs

Can I use chrome sockets on an impact wrench?

No. They’re designed for hand torque only—impact use can cause cracking or shattering.

Can I use impact sockets with hand tools?

Yes. They work fine but may feel bulkier and limit access in tight spots.

Are impact sockets always Cr-Mo and chrome sockets always Cr-V?

Often, but not always. Heat treatment and geometry matter just as much as the alloy.

Which lasts longer?

Depends on use—impact sockets last longer on impact tools; chrome sockets last longer on hand tools.

Do I need both?

If you use both impact tools and hand tools for torque-sensitive work, yes—each has its own role.

Conclusion

Impact sockets are your go-to for any job involving impact tools. Chrome sockets excel in precision hand work and tight spaces. Keeping both in your toolbox ensures safer, faster, and more reliable results—while extending the life of your tools and your fasteners.

If you’re looking for high-quality impact and chrome sockets that meet industry standards, visit Kafuwell for a full range of professional-grade tools, or download our complete tool catalog.