Choosing the right grinding disc is a crucial decision that can determine the success or failure of your project—whether you’re working on a DIY task at home, doing metalwork in the garage, or tackling heavy-duty professional jobs. Anyone who has used an angle grinder knows that not all discs are created equal. The wrong disc can lead to excessive sparks, wasted time, and even safety hazards.

This article will walk you through the key types of angle grinder discs, their advantages, and how to choose the best one for your specific needs—so you can work more efficiently, more safely, and with better results.

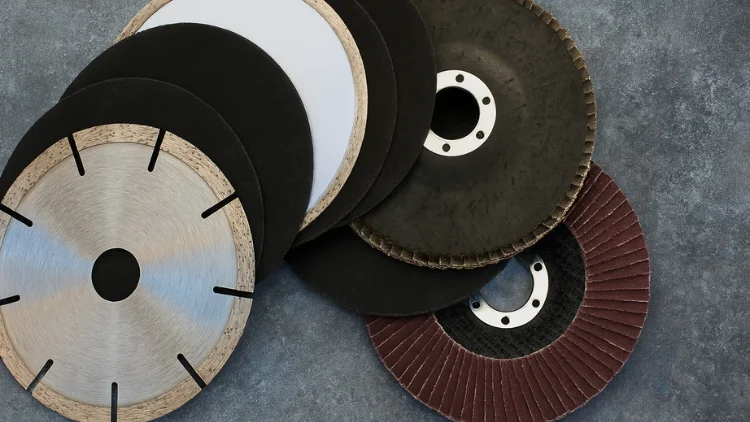

Understanding Angle Grinder Discs

An angle grinder (sometimes referred to as a cut-off machine) is a versatile power tool used for grinding, cutting, surface prep, and polishing. What makes it so adaptable is the wide range of discs you can pair it with—each designed for a specific task.

With so many options on the shelf, it’s easy to feel overwhelmed. Some discs are designed for grinding, others for cutting, and newer models offer performance far beyond traditional discs. But make no mistake: not all discs work the same, and using the wrong one can result in poor results, wasted material, or even damage to your tool or workpiece.

Here are the most common types of discs you’ll encounter:

- Grinding Discs

- Flap Discs

- Cutting Discs

- Diamond Discs

- Ultra-Thin Cutting Discs

Grinding Discs

These are usually the first type of disc most people encounter. They are relatively thick—typically around 8 to 10 mm—and are made from resin-bonded abrasive material. Their job is to grind metal, not to cut it.

Pros:

Durable and long-lasting

Effective for heavy stock removal

Great for grinding in tight corners

Cons:

Heavy and spark-intensive

Produces strong vibration

Poor at cutting—rough edges, slow speed, unsafe

Flap Discs

Flap discs have gained popularity among experienced users and professionals. Instead of a solid disc, they’re made up of overlapping abrasive flaps—like a sanding fan.

Why they’re better for many tasks:

Fewer sparks and less vibration

Smoother, more controlled grinding

Cleaner surface finish with minimal gouging

Combines grinding and finishing in one pass—ideal for weld blending and surface prep.

When Should You Use a Flap Disc?

Flap discs are the go-to choice for large-area metal grinding and when you want a smooth finish on welded seams. In extremely tight or confined spaces, however, traditional grinding discs still hold an advantage.

Flap discs commonly come in grit sizes ranging from 40 to 120. The lower the number, the coarser the abrasive—ideal for heavy material removal. Higher grits produce finer finishes, making them better suited for surface refinement and polishing.

For example:

40 grit is great for initial weld smoothing

80 grit works well for general metal surface prep

120 grit is best for fine polishing tasks

Resin-Bonded Cutting Discs

Resin-bonded cutting discs have been widely used for many years. Typically made with resin-bonded abrasive materials, they are suitable for cutting both metal and stone.

Advantages of Resin Cutting Discs:

- One of the most common and affordable options on the market, making them ideal for one-time or light-duty use.

- Strong cutting ability—can quickly slice through thin metal or stone materials.

- Versatile in application, with specialized models available for different materials such as steel, stainless steel, and stone.

- More flexible than metal-core blades, offering a smoother feel and better control under light operating conditions.

However, they also come with some notable drawbacks:

- Generate a significant amount of dust and debris during cutting, which can affect health and the environment.

- Wear out quickly and require frequent replacement.

- Prone to cracking or breaking, posing potential safety hazards.

Diamond Cutting Discs

Diamond discs have revolutionized the cutting process. Built on a steel core with an edge embedded with diamond grit, they deliver cleaner cuts and longer life.

Two main types:

- Segmented Diamond Blades: Feature notches along the edge for cooling. Ideal for cutting concrete, brick, and stone with minimal debris.

- Continuous Rim Blades: Smooth-edged blades made for delicate materials like tile and glass, offering clean, chip-free cuts.

Diamond blades are now widely available and much more affordable than before. If you’re frequently cutting stone, tile, or metal, a diamond blade is a smart investment.

Ultra-Thin Cutting Discs for Metal

Ultra-thin cutting discs have become a rising star among angle grinder wheels. They are typically made from white fused alumina or brown fused alumina abrasives bonded with phenolic resin, and reinforced internally with fiberglass mesh—striking a balance between an ultra-thin profile and reliable strength and safety.

With a typical thickness of just around 1 mm, these discs may look delicate, but they cut through various metals with remarkable efficiency, requiring minimal effort and leaving behind clean, smooth edges.

Advantages:

- Minimal heat buildup

- Clean cuts with very little burr

- Quickly cuts through thick metal, pipes, and rods

- Energy-saving and long-lasting — one disc can make many cuts

Safety Tip:

Because ultra-thin 1 mm discs are very brittle, never twist or apply lateral force while cutting, as they can easily break. Always keep the cutting motion straight and strictly follow angle grinder safety procedures.

Quick Reference Table: Which Disc for Which Task?

| Disc Type | Thickness | Best Use | Pros | Cons |

| Grinding Disc | 8–10 mm | Heavy grinding, corners | Durable, strong material removal | Sparks, rough edges, unsafe for cutting |

| Flap Disc | 3–5 mm | Welds, surface finishing | Smooth finish, low vibration | Not for corners, can’t cut |

| Resin-Bonded Cutting Disc | 2–3 mm | Everyday metal/stone cuts | Cheap and accessible | Wears fast, dusty, fragile |

| Segmented Diamond Blade | 2–4 mm | Stone, concrete, brick | Long life, clean cut, low debris | Higher upfront cost |

| Continuous Rim Diamond Blade | 2–3 mm | Tile, glass, thin materials | Cleanest cuts, chip-free edges | Niche applications |

| Ultra-Thin Cutting Disc | ~1 mm | Fast, fine metal cutting | Clean, fast, minimal effort | Brittle—no side pressure |

How to Read the Back of a Grinding Disc

Choosing the right disc isn’t just about type—it’s also about reading the label. Many users focus only on appearance or usage, but the disc’s backside label contains crucial specs that affect safety and performance.

1. Maximum Speed (Max RPM)

This indicates the disc’s safe operating speed. Always ensure your grinder’s RPM is equal to or less than the disc’s rated speed to avoid risk of explosion.

Example: If a disc says 12,200 RPM and your grinder tops out at 11,000 RPM, you’re good to go.

2. Size & Dimensions

Usually marked as Diameter × Thickness × Arbor Hole, such as “125mm × 6mm × 22.23mm”.

- Diameter determines compatibility and cutting depth

- Thickness affects grinding aggressiveness

- Arbor hole must match your grinder’s spindle

3. Material & Application

Labels often state: “For steel”, “For stainless”, “For aluminum”, etc. Always match the disc to the material to avoid poor performance or safety hazards.

4. Certification & Safety Marks

Look for industry standards like EN12413, MPA, or ISO9001—these indicate the disc meets safety and quality benchmarks.

5. Batch Number & Expiry Date

Discs do expire. Resin-based discs can absorb moisture over time, weakening their structure. Replace expired discs even if they appear unused.

6. Warning Icons

You may see icons like “Wear goggles” or “Do not apply side pressure”. Always follow these for your safety.

FAQs

Can I Use One Disc for Multiple Materials?

Not recommended. For example, using a steel disc on aluminum or wood can cause clogging or excessive wear. Always check the manufacturer’s label.

When Should I Replace a Disc?

Replace it if you see cracks, chips, heavy wear, or if the disc wobbles. Don’t wait for it to fully break down.

Are There Universal Discs?

Not really. Some multi-purpose discs exist, but they rarely excel at any one task. It’s better to use the right disc for each job.

What if the Disc Gets Stuck?

Turn off the grinder and unplug it. Never force it out—doing so can damage both the disc and your tool.

Can I Keep Using a Damaged Disc for a Quick Job?

Absolutely not. Even a minor crack can cause a disc to shatter at high speed. Always discard damaged discs.

Why Do Discs Have a Front and Back?

Discs are designed with a front and back for safety and performance. The labeled or raised side is usually the back. Proper orientation ensures better clamping, balance, and safe operation.

Conclusion

Learning how to choose the right grinding disc isn’t just about getting the job done—it’s also about safety, efficiency, and delivering the best possible results.If you’re looking for high-quality grinding discs at great value, or if you want to upgrade your tools, feel free to browse our product list. You’ll also find a wide selection of cost-effective products on our website to meet all your needs.