If you’ve paid attention to power tools, you may have noticed the term “brushless.” Many brands promote brushless technology as a premium feature, claiming it offers better performance and higher efficiency. But what exactly does “brushless” mean? And why does it matter to you?

In this article, I’ll clearly explain what brushless technology means in power tools, how it differs from traditional brushed motors, and whether it’s the right choice for your needs.

What Does “Brushless” Mean in Power Tools?

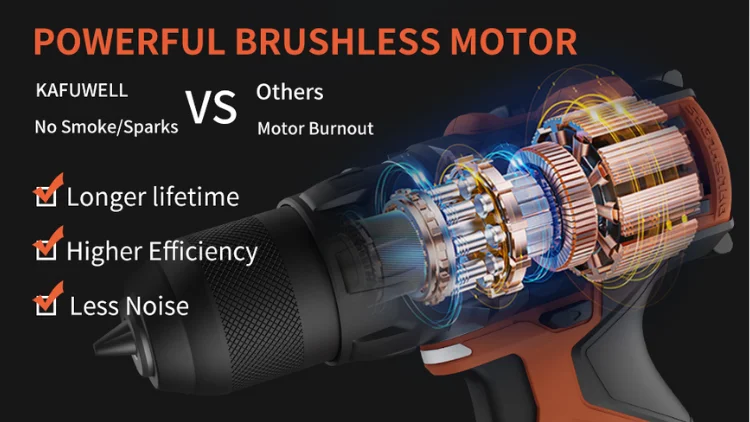

Simply put, a brushless motor is an electric motor designed without the carbon brushes traditionally used to transfer electrical current. In power tools, this means there’s no physical contact between moving parts inside the motor, reducing friction, wear, and energy loss.

To make it even clearer: traditional motors, known as “brushed motors,” rely on tiny carbon brushes to transmit power. These brushes physically contact spinning parts, causing friction and heat. Brushless motors, on the other hand, use electronics such as advanced sensors and circuit boards to control the power flow precisely, eliminating the need for brushes altogether.

So, when you see “brushless” on a drill or saw, it indicates the tool is powered by this advanced motor type.

How Do Brushed and Brushless Motors Work?

Understanding how motors work can help you determine whether brushless technology is worth the investment. Let’s compare the structure and operating principles of the two types of motors:

Brushed Motor

A brushed motor consists of the following key components:

- Rotor (Armature): The rotating part of the motor

- Stator (Magnets): Fixed magnets surrounding the rotor that generate a magnetic field

- Carbon Brushes: Maintain contact with the rotating rotor to deliver current to the internal coils

Electric current flows through the carbon brushes into the rotor windings, generating a magnetic field. This field interacts with the stator’s magnets, causing the rotor to spin. However, the friction between the brushes and rotor produces heat and leads to gradual brush wear, which reduces efficiency over time.

Brushless Motor

A brushless motor uses a completely different structure:

- Rotor: Usually contains fixed permanent magnets

- Stator: Made of electromagnetic coils and remains stationary

- Electronic Control Unit (Controller): Precisely switches the current in the coils in real time to create a rotating magnetic field

The electronic control system directs current through the stator coils in a sequence, simulating a rotating magnetic field that drives the rotor. This process eliminates the need for carbon brushes and avoids any physical friction inside the motor.

Key Differences Between Brushed and Brushless Power Tools

To simplify your decision, here’s a clear breakdown of the main differences between brushed and brushless motors in power tools:

| Feature | Brushed Motor | Brushless Motor |

| Efficiency | Lower efficiency due to friction. | Higher efficiency, no friction from brushes. |

| Power Output | Decent, but can drop under heavy loads. | Consistently higher, even under heavy loads. |

| Maintenance | Regular replacement of brushes needed. | Minimal to no routine maintenance required. |

| Heat Production | Higher heat due to friction. | Lower heat, runs cooler. |

| Noise Level | Usually louder, noticeable buzzing. | Quieter and smoother operation. |

| Lifespan | Shorter, brushes wear out over time. | Significantly longer due to reduced wear. |

| Price | Lower initial cost. | Higher initial cost, but cost-effective long-term. |

Typical Applications and Who Should Choose Brushless Tools

To clearly understand if brushless tools fit your needs, it helps to look at typical scenarios and real-world applications:

Professional Tradespeople and Contractors

If you’re a professional working daily in construction, woodworking, plumbing, or automotive repairs, brushless power tools offer a noticeable upgrade in productivity and reliability. These tools handle heavy workloads and demanding tasks without overheating or losing power midway through a job.

Imagine using a cordless drill all day long on a single battery—this convenience alone makes brushless tools highly valuable for anyone earning a living from their tools.

Serious DIY Enthusiasts and Home Renovators

Brushless technology isn’t limited to professionals; if you’re regularly doing substantial home improvement projects, it’s worth the investment. Whether you’re remodeling a kitchen, building a backyard deck, or frequently tackling challenging DIY tasks, a brushless tool significantly improves your experience.

You’ll appreciate how these tools smoothly handle repetitive drilling, cutting, or fastening tasks without stalling or overheating—making your projects less stressful and more enjoyable.

Regular Home Maintenance

Even if you’re not an expert but regularly handle home repairs or maintenance tasks, brushless tools provide convenience and reliability. They’re especially useful if you value tools that require minimal upkeep.

For instance, if your toolset is primarily for regular maintenance tasks like assembling furniture, installing shelves, or occasional renovations, brushless tools offer longevity, reducing how frequently you’ll need replacements.

Occasional or Light Users

If you’re more of an occasional weekend warrior, tackling very basic tasks around the house, brushless tools might be overkill. In such cases, simpler brushed tools will typically suffice and save you money upfront. Consider carefully how frequently and intensely you’ll realistically use your tools.

Conclusion

Brushless power tools represent a meaningful step forward in power tool technology. Their efficiency, power output, durability, and ease of maintenance make them especially beneficial for frequent users or professionals.

If you’re considering upgrading your power tools or want to experience the efficiency and convenience of brushless technology, feel free to browse our official website or explore our power tool product list. We offer a wide range of reliable options to suit different needs and budgets. Start now and equip yourself with more professional tools for your next project!