If you spend much time in a workshop or enjoy DIY projects, you’ve probably seen an angle grinder (also known as a disc grinder or side grinder). This is a handheld power tool that can cut, grind, or polish a variety of materials.

Angle grinders are widely used everywhere—from metalworking shops and construction sites to home garages. With the right attachments, even beginners can use them for tasks like smoothing rough metal, trimming tiles, or cutting through stubborn bolts.

What Is an Angle Grinder?

The tool gets its name from the internal gear system that allows the grinding disc to spin at a right angle to the tool’s body. This design gives users better control and makes it easier to reach into tight corners.

To use an angle grinder safely and effectively, you should first get to know its structure. Although there are many models and sizes, the basic principles are the same. Before turning one on, make sure you understand its key parts, how to choose the right disc, and which machine best fits your needs.

Core Components of an Angle Grinder

Every angle grinder has a set of core components that work together to provide power and control. Most angle grinders include the following parts:

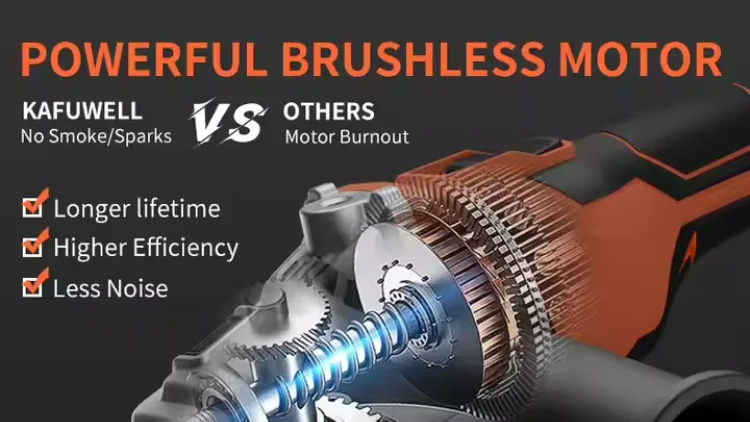

- Motor: The heart of the tool, converting electricity (or compressed air) into high-speed rotation.

- Gearbox: Changes the direction of rotation, positioning the grinding disc at a right angle to the body, which is ideal for surface work and working in tight spaces.

- Spindle: The short shaft extending from the gearbox, where various attachments are mounted. Most grinders have a spindle lock for quick disc changes.

- Guard: A semi-circular metal shield that covers part of the disc, protecting you from sparks and debris. Most guards can be rotated to adjust the angle.

- Handles: Typically includes a main handle and a side handle. The side handle provides better control, especially during heavy-duty work.

- Discs/Wheels: The interchangeable part of the tool. With the right disc, you can cut, grind, polish, or remove rust—all with a single tool.

These components work together to make the angle grinder both safe and easy to use. Always keep your hands clear of the spinning disc, and use the guard correctly to prevent accidents. Most angle grinders come with a basic user manual—if you’re new to the tool, read it before your first use.

Types of Angle Grinder Discs and Their Uses

Different discs are designed for different materials and tasks. Choosing the right disc makes your work easier and keeps you safe.

Common types of discs include:

- Grinding Wheels: For smoothing or shaping rough metal edges.

- Cutting Discs: Thin, fast-cutting wheels, perfect for slicing through metal rods, bolts, or rebar.

- Flap Discs: Made from layered sandpaper, these are great for blending welds, removing paint, or shaping wood.

- Diamond Blades: Specifically for cutting stone, concrete, tile, or other hard materials.

- Wire Wheels/Brushes: For removing rust, old paint, or cleaning metal parts.

- Polishing Pads: Used for polishing metal or stone surfaces to a shine.

Each attachment is designed for a specific job. Thin discs are best for cutting, thicker ones for heavy grinding, and wire brushes for surface cleaning.

Safety Tips for Using Attachments

Whenever you’re changing or using attachments, remember these safety basics:

- Always install the safety guard—it’s your best defense against flying debris.

- Wear safety goggles and a face shield. A full face shield can prevent serious injury if a disc breaks.

- Cutting discs are more fragile than grinding wheels—handle and use them with extra care.

How to Choose the Right Angle Grinder

Picking the right angle grinder can save you a lot of hassle. Before you buy, consider these factors:

Power Source

- Corded (Plug-In): Great for long jobs—no worries about running out of power. The downside is that cords can limit your movement.

- Cordless (Battery-Powered): More portable, ideal for tight spaces or places without outlets. Just remember, batteries eventually run out, so keep a spare or a charger handy.

Size

One of the biggest differences among angle grinders is disc diameter, which affects what kind of work you can do and how easy the tool is to handle.

- 4.5-inch: The most common size for beginners and hobbyists, and a staple in many pro shops. It balances cutting power, size, and weight.

- Other Sizes: You’ll also find 5-inch, 6-inch, 7-inch, and even 9-inch grinders. Larger tools are more powerful and can cut deeper, but they’re heavier and harder to control. For most users, 4.5 inches is more than enough.

Motor Power

Motor strength is usually measured in amps:

- 8 amps: Good for home use or light professional work. Lightweight and budget-friendly.

- 11 amps: More powerful, suitable for cutting or grinding larger materials. These tools are heavier and more expensive.

Speed

- Most angle grinders run at 6,000 to 12,000 RPM.

- Higher speeds cut faster but wear down discs more quickly.

- If possible, choose a variable-speed model—it’s helpful for working with delicate materials.

Features and Build Quality

Besides the basics, look for features like water resistance, rust protection, and good heat dissipation.

For example, in areas prone to flooding (like Indonesia or the Philippines), tools with an IP67 waterproof rating are a smart choice. Housing and gearboxes with rust-resistant coatings or nickel plating can extend the tool’s life.

In the construction industry, high temperatures are common—good cooling and anti-vibration designs can make the tool much more comfortable and durable during long jobs.

Safety Certifications

Choose products with CE, UL, or similar certifications. For example, brands like Kafuwell offer affordable, reliable angle grinders with these safety marks.

learn more: What Is the Best Power Tool Brand?

Common Uses for Angle Grinders

Whether on a construction site or in a workshop, angle grinders are popular for their versatility and fast accessory changes. Here are some typical applications:

Metalworking and Fabrication

- Grinding: Smoothing out welds or rough edges for a clean, safe finish.

- Cutting: Slicing through pipes, bolts, rebar, or metal sheets with a cutting disc.

- Deburring: Removing sharp edges after drilling or sawing—prevents cuts and improves fit.

- Polishing: Prepping metal for painting or adding a mirror finish, common in auto body work and kitchenware.

Construction and Stonework

- Tile/Stone Cutting: Using a diamond blade to make precise cuts in tile, marble, or brick.

- Concrete Finishing: Adjusting the size of blocks or concrete slabs, making grooves or smooth edges.

- Surface Preparation: Leveling new concrete, removing extra mortar, adhesives, or paint.

Home Improvement and DIY

- General Repairs: Quickly removing rusty screws, wire mesh, or metal fittings.

- Restoration Projects: Wire brushes for cleaning rust or old paint from tools, grills, or outdoor furniture.

- Tool Sharpening: Touching up axes, lawnmower blades, chisels, and more—no need for a special sharpening tool.

- Custom Projects: Cutting tile, shaping wood, or even crafting DIY metal signs.

Summary

An angle grinder is one of the most versatile tools you can own. With the right disc and a little know-how, you can handle metal, stone, or home repairs with ease.Whether you want to equip your team with reliable angle grinders, need to purchase in bulk, or require customized solutions for your projects, the Kafuwell team is here to help.