If you’ve ever used a power tool or browsed for one online, you’ve probably seen the debate between brushed and brushless motors. Maybe you’ve wondered if the difference is all hype or if it really changes how the tool feels in your hand. The reality? The choice you make can affect power, efficiency, how often you swap batteries—and how much hassle you face down the road.

This guide breaks down what actually separates these two motor types, covers their real-world pros and cons, and helps you decide which one fits your needs best.

What is a Brushed Motor?

Brushed motors have been around for ages—and for good reason. The design is simple: carbon brushes press against a rotating commutator, which flips the current back and forth as the motor spins. This setup is what gets the shaft turning and the job done.

But the catch is friction: as those brushes rub against the commutator, they wear down. That means more maintenance, and eventually, you’ll need to replace the brushes to keep things running smoothly.

Key parts in a brushed motor:

- Brushes: These little carbon blocks are what transfer electricity, but over time they get shorter and need replacing.

- Commutator: This spinning part flips the current to keep the armature moving.

- Armature: The bit that spins and does the actual work.

- Stator: The stationary magnets or windings that create the magnetic field for the motor.

Brushed motors get the job done with a simple circuit and no fancy electronics, which is why they’re still popular in many entry-level and budget tools.

What is a Brushless Motor?

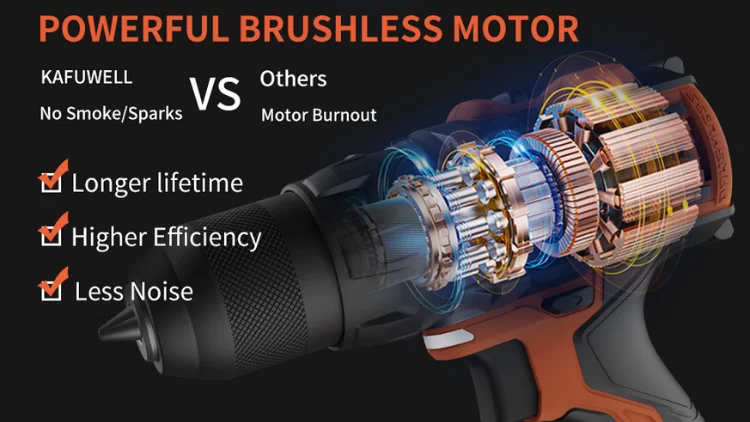

Brushless motors are the modern answer to many brushed motor headaches. Instead of relying on physical contact, brushless designs use magnets and a smart electronic controller to keep everything spinning. No brushes mean no friction, less wear, and no sparks flying inside the motor.

Key parts in a brushless motor:

- Rotor: Usually packed with permanent magnets, this spins and drives the shaft.

- Stator: Surrounds the rotor and is full of wire windings; energized by the controller to create motion.

- Electronic Controller: This is the “brains” of the operation, telling the stator coils exactly when and how much power to send, adjusting in real time for smoother, more efficient operation.

With brushless motors, you can get more power out of the same battery, less heat buildup, and a tool that just feels smoother under load.

Brushless Motor vs Brushed Motor

Efficiency and Performance

Friction is the main thing holding brushed motors back. As the brushes grind away, energy gets lost as heat, and the motor can only hit around 70%–80% efficiency—even less as it ages.

Brushless motors, on the other hand, have almost no internal friction, often reaching 85%–95% efficiency. For anyone who’s run back-to-back tests, the difference is clear: brushless motors last longer on a charge and hold their power better under tough loads.

Noise and Vibration

If you’ve used both types, you know the difference right away. Brushed motors have a distinctive hum and sometimes a little rattle as the brushes skip across the commutator. The longer you use them, the noisier they get. Brushless motors are noticeably quieter—no brush drag, no electrical noise—just a steady whir. Less vibration also means less user fatigue, which is a big deal on bigger jobs.

Durability and Lifespan

Brushed motors need regular checkups. Those carbon brushes are designed to wear out, and eventually you’ll need to swap them. For most users, that’s somewhere between 2,000 and 5,000 hours of run time. Not bad, but the drop in performance as brushes wear can be noticeable.

Brushless motors are a different story. No brushes mean fewer parts to wear out. Most failures come down to bearing wear or the electronics themselves—rare unless the motor’s abused. It’s not unusual for a quality brushless tool to run 10,000+ hours with nothing but an occasional cleaning.

Price

Here’s where brushed still wins: up-front cost. Brushed motors are easy to make and cheap to fix. Brushless motors need electronics and more precise manufacturing, which makes them about 30% pricier on average. But the gap’s getting smaller, and for heavy users, the payoff in efficiency and lower maintenance usually covers the higher initial price.

Safety

Sparks flying out the vents are normal for a brushed motor, especially under heavy load. In most settings it’s no big deal, but in dusty or flammable environments, that spark can be a hazard. Brushless motors run much cooler and don’t produce sparks—making them safer for job sites where safety matters.

Brushed vs Brushless Motors: Which Is Right for You?

Go brushless if:

- You use tools every day or for heavy work

- You want longer battery life and more torque in a lighter package

- Noise, vibration, and reduced maintenance are a priority

- You care about long-term value

Stick with brushed if:

You’re comfortable swapping brushes or don’t mind a bit of regular maintenance

You’re an occasional DIYer or just need a tool for simple jobs

Budget is tight and you don’t want to pay extra for features you won’t use

Conclusion

Both types of motors have their strengths. Brushed motors are straightforward and budget-friendly, making them a solid choice for light or occasional use. Brushless motors, on the other hand, deliver better efficiency, longer life, and a smoother user experience—ideal for anyone who uses their tools regularly or for demanding jobs.

If you want to build a reliable, long-lasting toolkit for work or frequent use, going brushless is a smart investment. But for simple home repairs or DIY projects, a brushed tool will do the job just fine—and help you save money.

Curious about the options? Take a look at KAFUWELL’s selection of brushed and brushless tools. Compare the specs, see what fits your needs.